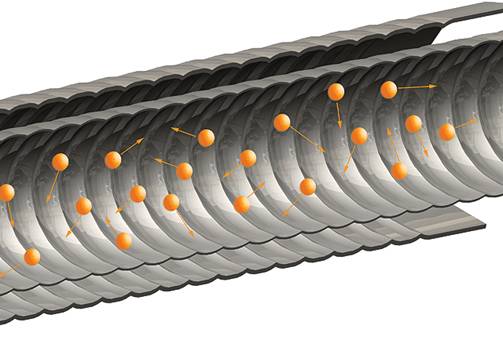

Turbulent flow inside the corrugated tubes due to it’s helical indentation enables a more effective mixing & agitation resulting in a high heat transfer coefficient.

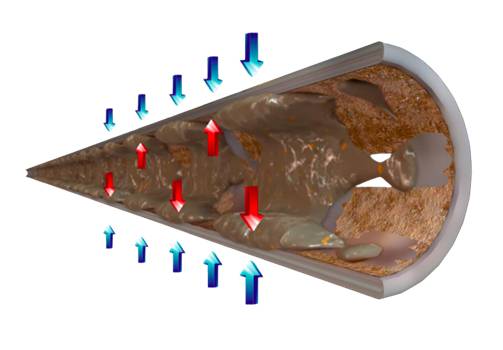

Drop wise condensation resulting in better condensation compared to thin film formation in plain tubes. The corrugation provides a channel to the condensate layer formed on the surface of tube, always providing a fresh new surface for the vapours condense.

Higher periphery turbulence does not allow the suspended solid particle in the tubes to settle, thus giving is a self-cleaning effect which results in reduced fouling that ensure longer running time. Easier to clean due to intermittent scaling as compared to Plain tube.

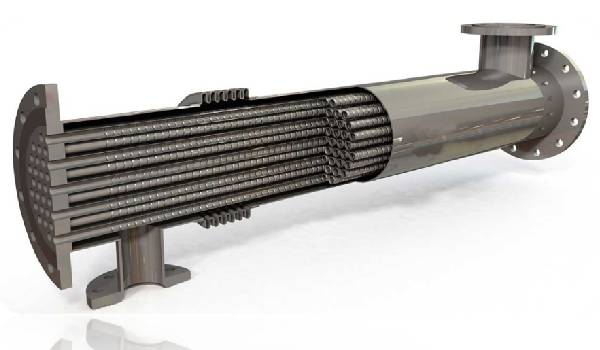

At Rahul Engineering Global Pvt. Ltd., our commitment to excellence drives us to develop cutting-edge heat exchanger solutions that redefine efficiency, reliability, and performance in heat transfer applications across various industries.

1. Optimized Heat Transfer: Our innovative corrugated tube design significantly enhances the heat transfer coefficient, ensuring superior performance compared to conventional tube heat exchanger.

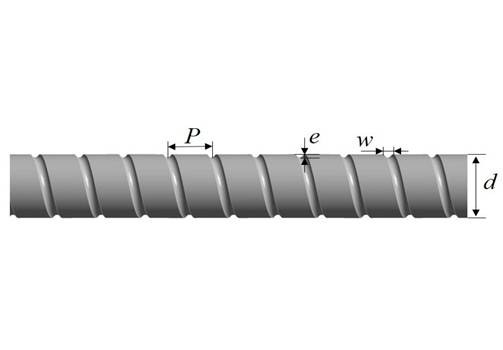

2. Increased Surface Area: The precisely engineered corrugations on the tube surface maximize the contact area between fluids, enabling efficient heat exchange while minimizing pressure drop.

3. Versatility and Durability: Crafted from high-quality materials, our heat exchangers are designed to withstand extreme temperature and pressure conditions, ensuring longevity and reliability.

4. Compact Design: With a focus on space efficiency, our heat exchangers offer a compact footprint, making them ideal for applications where space is at a premium.

Chemical Processing: Ideal for heating and cooling various chemical processes.

Food and Beverage: Ensures efficient pasteurization and temperature control in food processing.

1. Expert Engineering: Our team of experienced engineers employs advanced techniques and innovative designs to deliver state-of-the-art heat transfer solutions.

2. Tailored Solutions: We understand that each application is unique. Hence, we offer customized designs to meet your specific requirements.

3. Quality Assurance: Rigorous quality checks at every stage of manufacturing ensure that our products adhere to the highest industry standards.

We at Rahul Engineering Global Pvt. Ltd. are excited about the prospect of offering you our expertise in thermal solutions through our Corrugated Tube Heat Exchanger. We believe this innovative technology will elevate your operations to new levels of efficiency and reliability.

Please don't hesitate to contact us for further information or to discuss how our Corrugated Tube Heat Exchanger can meet your heat transfer needs. We look forward to the opportunity to serve you and contribute to your success.