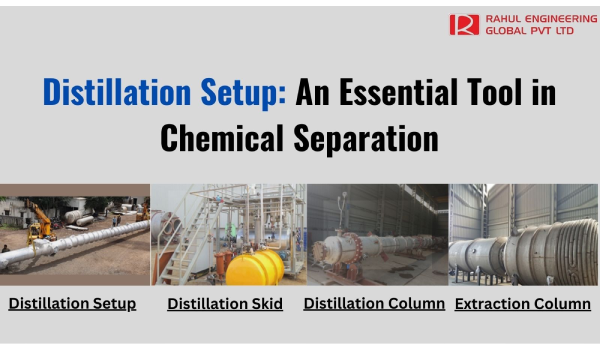

Distillation is a fundamental process used in various industries to separate and purify different components of liquid mixtures based on their boiling points. The distillation setup, comprising various components like distillation columns, skids, and extraction columns, plays a pivotal role in this process. Let's delve deeper into understanding what a distillation setup is, its key benefits, advantages, working principles, and the different types of components it encompasses.

What is a Distillation Setup?

A distillation setup is an apparatus designed to facilitate the distillation process, allowing the separation of liquid mixtures into their individual components by exploiting differences in boiling points. It typically comprises various components working together to achieve efficient separation, such as distillation columns, skids, condensers, boilers, and extraction columns.

Key Benefits of a Distillation Setup:

1. Separation and Purification:

- Enables the separation of components in liquid mixtures, purifying them for specific applications.

2. Versatility:

- Applicable across industries like pharmaceuticals, petrochemicals, food and beverage, and more.

3. Scalability:

- Distillation setups can be designed for various scales of production, from laboratory use to industrial-scale operations.

4. Resource Efficiency:

- Allows for the reuse and recycling of solvents and chemicals, contributing to sustainability efforts.

Advantages of a Distillation Setup:

- High Purity Output: Offers high-purity components by effectively separating substances with close boiling points.

- Cost-Effectiveness: Facilitates cost savings by reducing the need for additional purification processes.

- Process Control: Provides precise control over temperature, pressure, and flow rates, optimizing the separation process.

How does a Distillation Setup Work?

Distillation Column:

A crucial part of the setup, the distillation column, operates on the principle of continuous fractional distillation. It consists of trays or packing material where the liquid mixture enters from the top and is heated. Components with lower boiling points vaporize, rise through the column, condense, and are collected, while heavier components remain liquid and exit from the bottom.

Types of Distillation Components:

- A compact, pre-engineered system comprising multiple components (such as pumps, heat exchangers, and control systems) mounted on a single frame. It's easily transportable and quick to install, ensuring efficiency and ease of operation.

- Various types include fractionating columns, packed columns, and tray columns. They differ in their internal structures, affecting efficiency and suitability for different applications.

- Often used in processes like liquid-liquid extraction, an extraction column facilitates the separation of components based on their solubility in different phases.

Conclusion:

Distillation setups are indispensable tools for industries requiring precise separation and purification of liquid mixtures. Their versatility, efficiency, and ability to cater to different scales of operation make them vital for various industrial processes, ensuring high-quality and pure end products. Understanding the components and working principles of distillation setups helps optimize their usage across diverse applications.

Rahul Engineering Global Pvt. Ltd. specializes in the design and production of advanced distillation setups catering to various industries. Our state-of-the-art distillation setups are meticulously engineered to ensure optimal efficiency and precision in separating and purifying liquids. Equipped with cutting-edge technology, our setups are customizable to meet specific client needs, offering a range of capacities and configurations. Whether for the pharmaceutical, chemical, or food and beverage sectors, our distillation setups are crafted with the highest quality materials, adhering to industry standards and designed to deliver superior performance, reliability, and ease of operation. Rahul Engineering Global provides Pune, India's best DISTILLATION SETUP Manufacturers. We offer different types of Products such as Distillation Setup, Batch Distillation Column, Distillation Skid, Distillation Columns. Trust Rahul Engineering Global Pvt. Ltd. for innovative distillation solutions that exceed expectations and enhance your production processes.