Heat exchangers also known as heat transfer systems do what the term involves. They change the temperature of liquids that pass through them. The significant to heat exchangers is the large superficial capacity of copper tubes. Heat is transferred quickly in liquids and gases by conductive and convective mechanisms. Cooling tower manufacturers have found a process to harness this natural phenomenon to provide efficient cooling for industrial uses

What Is A Heat Exchanger?

A heat exchanger is a method that transfers heat from one fluid to additional. The fluid may be a gas or liquid, which can transmission heat by convection, conduction, or radiation. There are certain categories of heat exchangers, containing the shell-and-tube type, plate type, and tubular finned tube type.

How Does A Heat Exchanger Work?

A heat exchanger is a device that transmissions heat from one fluid to extra. The fluid may be a gas or liquid, which can transmission heat by convection, conduction, or radiation. A heat exchanger transfers heat from one fluid stream to another through straight physical contact between the dual streams. The main change amid unlike types of heat exchangers is how they are constructed and what type of fluids they use.

For example, a steam producer uses steam as together its contribution and output fluid streams. It consists of tubing coils covering fine tubes called finned tubes with fins attached along their length, so they resemble small radiators. Vapor reaches at one end and departures at the further after being cooled by an outside average, such as water or air passing over these finned tubes inside the coil.

Types of Heat Exchangers

Heat exchangers are plans that transfer heat from one medium to additional. They are used in many uses, including the cooling of engines, gas condensing, and even water heating.

In a heat transfer system, two fluids flow previous each previous. One fluid must be hot, and the additional must be cold. The two fluids should not mix together, so they should have dissimilar densities and viscosities (properties that affect how easily they flow). When they meet inside a manufacturing exchanger, they exchange their heat but not their mass; this is called “adiabatic” exchange (meaning no work was done by friction).

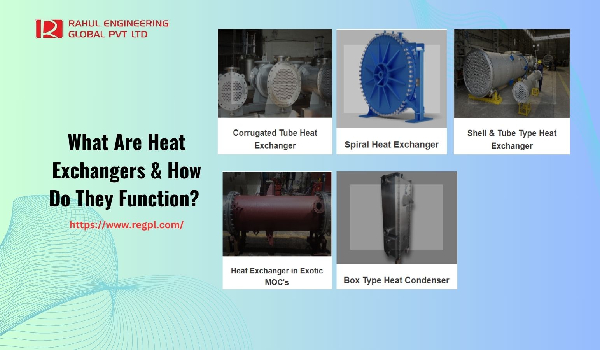

1. Shell & Tube Type Heat Exchanger:

The shell and tube heat exchanger is a widely used design consisting of a cylindrical shell with a bundle of tubes inside. Fluid flows through the tubes, while another fluid surrounds the tubes in the shell. This design allows efficient heat transfer, making it suitable for various industrial applications such as chemical processing and power generation.

2. Corrugated Tube Heat Exchanger:

Corrugated tube heat exchangers feature tubes with a corrugated surface, enhancing heat transfer efficiency. The corrugation disrupts laminar flow, promoting turbulence and improving heat exchange rates. This design is employed in applications where maximizing heat transfer in a compact space is crucial, like HVAC systems and certain chemical processes.

3. Spiral Heat Exchanger:

The spiral heat exchanger has a unique spiral flow path for two fluids, preventing mixing while facilitating efficient heat transfer. Its compact and self-cleaning design makes it suitable for applications with fouling or high-viscosity fluids. Industries like wastewater treatment and pharmaceuticals benefit from the spiral heat exchanger's versatility.

4. Box Type Heat Condenser:

The box type heat condenser is a compact and straightforward design where a fluid undergoes a phase change, typically from vapor to liquid, releasing heat in the process. This type of heat exchanger is commonly used in refrigeration and air conditioning systems, as well as industrial processes requiring condensation.

5. Heat Exchanger in Exotic MOC's (Materials of Construction):

Heat Exchanger in Exotic MOC's can be constructed from exotic materials to withstand corrosive or extreme operating conditions. Exotic MOC's, such as titanium, Hastelloy, or graphite, offer superior resistance to chemical corrosion. These specialized heat exchangers find applications in industries like petrochemicals, pharmaceuticals, and metallurgy where standard materials may not suffice.

Industrial Exchangers

Heat exchangers are used in numerous trades, including oil and gas, chemical, petrochemical, pharmaceutical, and power generation. They can be found in thermal plants, refineries and power stations, and former manufacturing procedures.

Heat exchangers are recycled for heating or cooling fluids or gases. These fluids may be liquids or gases. Heat exchangers are usually used to transport heat from one place to another by changing the heat of one fluid using additional fluid.

Call rahul engineering global pvt ltd today!

Heat exchangers are used to transfer energy concerning double varied forms. The most joint heat exchangers repaired in transporting thermal energy transferred between different fluids in a heat exchange progression. Heat exchangers are allocated into two major classes: “condensers” and “evaporators.” Condensers use steam, while evaporators use air circulated past electrically or gas-fired coils or added reheating devices to transfer heat energy.

Read on to learn more about heat exchangers and their purpose from rahul engineering global pvt ltd