The Corrugated Tube Heat Exchanger, distinguished by its unique design and superior heat transfer efficiency, enjoys higher demand compared to plate-type heat exchangers. If you seek such advantages, look no further than Process Engineers and Associates. As premier manufacturers of Corrugated Tube Heat Exchangers in Pune, we leverage our extensive industry expertise to provide robust and dependable solutions tailored to meet a wide array of industry requirements.

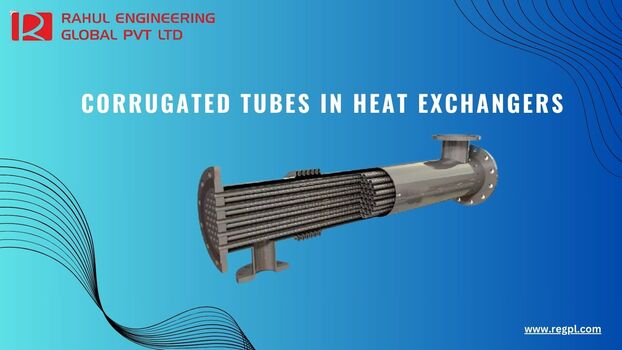

Corrugated tubes are integral components within heat exchangers, crucial for optimizing heat transfer efficiency. At Rahul Engineering Global Pvt. Ltd., our corrugated tubes are meticulously crafted to enhance thermal performance. These tubes feature a unique corrugated structure that significantly increases surface area, facilitating improved heat exchange compared to conventional smooth tubes.

Engineered with precision and using high-quality materials, our corrugated tubes ensure durability and reliability in diverse industrial settings. The corrugated design induces turbulence within the fluid flow, promoting efficient mixing and heat transfer between the fluid inside the tube and the surrounding medium.

The advantages of utilizing corrugated tubes in heat exchangers include enhanced thermal efficiency, reduced fouling, and minimized pressure drop. These benefits make our corrugated tubes ideal for a wide range of applications across industries such as HVAC, chemical processing, power generation, and more.

At Rahul Engineering Global Pvt. Ltd., we prioritize innovation and excellence, delivering corrugated tubes that surpass industry standards and cater to the specific needs of our clients. With our expertise and commitment to quality, we provide reliable solutions for efficient heat exchange processes.

Primary Motives for Choosing Corrugated Tube Heat Exchangers:

- Increased Efficiency: Using it may prevent viscous fluids and suspensions from creating an insulating boundary layer on the tube surface, which ensure better efficiency.

- Streamlined Maintenance and Cleaning: With no moving components, these heat exchangers facilitate effortless inspection, cleaning, and maintenance, resulting in substantial savings in terms of plant resources, manpower, and costs.

- Ease the Process: With Industrial Corrugated Tube Heat Exchanger, heat transferring between fluids or gases becomes easier. Corrugated tube heat exchangers offer several benefits compared to traditional smooth tube heat exchangers:

- Enhanced Heat Transfer: The corrugated design of the tubes increases the surface area available for heat transfer. This results in improved heat transfer efficiency, allowing for better performance in terms of heating or cooling.

- Reduced Fouling: The corrugated structure disrupts laminar flow and helps prevent fouling by promoting turbulence, which reduces the buildup of deposits on the tube surface. This leads to longer intervals between cleaning and maintenance, reducing downtime and operating costs.

- Compact Design: Corrugated tube heat exchangers typically have a more compact design compared to traditional smooth tube heat exchangers. This allows for more efficient use of space, making them suitable for applications where space is limited.

- Higher Thermal Efficiency: The enhanced heat transfer capabilities of corrugated tube heat exchangers result in higher thermal efficiency, meaning they can achieve the desired temperature change with less energy input compared to smooth tube heat exchangers.

- Improved Resistance to Thermal Stress: The corrugated design provides greater structural strength and flexibility, allowing the heat exchanger to better withstand thermal stress and pressure fluctuations. This can contribute to longer equipment lifespan and reduced maintenance costs.

- Versatility: Corrugated tube heat exchangers can be designed and manufactured to meet specific application requirements, including variations in material, size, and configuration. This makes them versatile and adaptable to a wide range of industrial processes and operating conditions.

- Cost-effectiveness: While the initial investment may be slightly higher compared to smooth tube heat exchangers, the long-term benefits, including improved efficiency, reduced maintenance, and longer equipment lifespan, often result in overall cost savings over the life of the equipment.

- Overall, corrugated tube heat exchangers offer a combination of improved heat transfer efficiency, reduced fouling, compact design, and versatility, making them a preferred choice for many industrial heating and cooling applications.

-

Dial Our Number Now!

Rahul Engineering Global Pvt. Ltd. is the best Corrugated Tube Heat Exchanger Supplier, Manufacturer Company in Pune, India.As leading exporters and suppliers of Corrugated Tube Heat Exchangers in India, we assure prompt delivery and comprehensive customer assistance. Reach out to us with your inquiries or call us for further information.